Lo-Pressure Urethane Molding

Prototype and Short Runs

A Great Alternative to Injection Molding

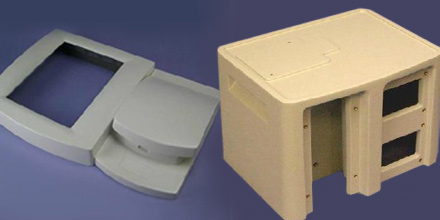

We encourage you to consider us for your next project requiring short run plastic components. We mold a rigid thermoset urethane in RTV silicone molds. Shrink marks, draft angles and part size are never an issue, as they are with injection molding, and volumes of 10-30 units per month are ideal. This process is ideal for covers, bezels, and housings. Save your capital for other programs. Our tooling is a fraction of the cost of injection molds and basically you “pay as you go”. Tooling cost is non-recurring. Many satisfied customers come to us whether they require only prototype or pre-production parts prior to hard tool construction, or prefer to stay with our process for the life of their product. Dimensional changes are made fast and very inexpensively, so it is a great way to launch a new product.

The material is much like a high impact ABS (specs will be sent at your request), with a UL-VO flame rating available. Delivery… typically 2 weeks or less for first production parts. Let us know if you need to accelerate the lead time!

Usually your quote is available within 48 hours of receiving your files. All under one roof, we offer engineering enhancement, models, molding, all secondaries including finishing and screening. We encourage you to visit our New England location conveniently located off I95, about 2 hours from NYC.

Thank you, in advance, for your consideration. Let us know how we can assist and how we can provide you with

“a great alternative to injection molding.”

ALSO CONSIDER US FOR RAPID PROTOTYPE MODELS MADE VIA THE FDM PROCESS.

We now have Stratasys 3D Printers (OBJET

30-PRO and FORTUS-400M) in house.