PATTERNS Plaster mold casting is a split pattern technique. Tooling consists of a permanent machined pattern made in two parts. The cast part shape is divided along a parting line that is established to provide the best tolerance advantage with no undercuts.

If undercut features are needed, cores are produced separately in precision core boxes and placed in the mold halves. Design changes are quickly and inexpensively accommodated.

MOLDS The plaster mold components are made by mixing a slurry which is poured over the patterns. Only a minimum of molding draft is required in the pattern.

Cured mold halves are placed in a drying oven at 300-500 degrees F for one to two days. The mold halves are then precisely doweled together and clamped.

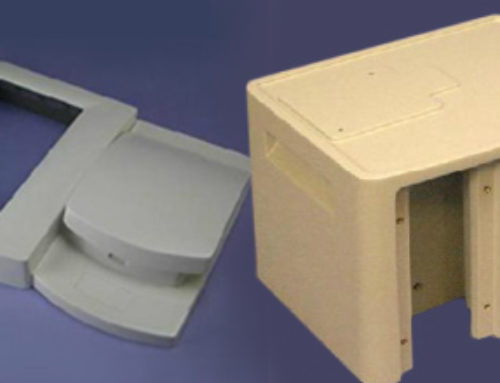

CASTINGS molten metal is poured into assembled molds. Once the metal has cooled, the plaster is carefully broken away with high pressure water. Gates and parting lines are ground away, and the part is cleaned up in an abrasive blast chamber, giving the surface a fine finish. Parts can be made to such close tolerances that secondary machining is often eliminated.

We manufacture aluminum and zinc castings for the United States military and commercial applications from computer-aided designs, and provide masters using conventional model-making or stereo lithography patterns. Available precision metal casting alloys include A356, C 355, 4OE Tenzalloy and ILZRO number12 zinc. The company’s applicable specifications include QQ-A-596, MIL-I-45208 A, MIL-A-21180 and MIL-STD-2175.